16' Sylvan Aluminum Boat

|

Breathing New

Life in a 30 Year Old 16' Sylvan Aluminum Boat

|

I thought I would never sell my 2005 18' North River Mariner boat, which in I

purchased used in 2009, where I had taken a basic bare boat and over the years

(16) that I owned it, I had made it into a real fishing machine.

However with health issues creeping up on me, (bad lower back issues, COPD and

wet Macular Degeneration) along with where I had only gotten this boat's bottom

wet once in over 3 years basically because of my low back issues. All

this, and my age (89), my priorities have changed considerably, along with the

fact that about all my fishing partners have passed away, OR the younger ones

own their own boats. My son is so busy in his small family business

that he can't take much time off, and the grandsons are scattered. I have

tried to introduce younger people into my style of fishing, but they also have a

life that oftentimes interferes with fishing. Therefore, I very OFTEN fish

alone, (at the dismay of my adult kids). However I am pretty darned safety

cautious, and have seen to many stupid things done in my day. And on any of my boats, I have about all the safety

provisions there, in place, and they are all OPERATIVE.

I am sure that a smaller/lighter

boat would be easier to handle alone at launch/recovery time for this old

GEEZER.

I might add that for an old Geezer I am quite active, (well - as much as my

medical disabilities allow).

Now instead of ocean fishing being one of my prime spots, my sights

have shifted toward Puget Sound, or the local bays, / tidewater, lower river sections in the fall for

returning salmon. And possibly some crabbing. This change is mainly due to the salmon seem to have

moved out into DEEPER/COLDER ocean water which means longer runs offshore (like

25 + miles one way) and if it gets rough in the afternoon on the way back in, not so good on my

low back issues, as compared to 5-8 miles on smoother water in the bays and even less on

the rivers. This farther run is partly

because of water temperature, and feeding habits where the salmon follow the bait,

created some by commercial herring/sardine seining nearshore.

Then with my North River boat (which is not really a offshore boat) I have had to closely

watch the weather and timing with the tides, (Ideally go out in the morning on low and come back on

high), which cuts down on fishing time on the water, as

compared to if It was a larger Deep Vee rougher water boat.

These newer locations (but not foreign to me however) and will include the lower Columbia

River

(buoy 10), Columbia River upriver to Woodland area, the Willapa Bay, the lower Chehalis, and southern

Puget Sound, and then closer to home, possibly some sections of the Cowlitz River. Then also this smaller boat

would also be more conducive to lake fishing if I really get desperate for a

boat ride.

Enter Boat # 28 ;

(For a link explaining this

number CLICK HERE).

Maybe I should add here before we go to far here, is that I have owned, made and fished

out if so many boats in my lifetime years,

starting at age 10 (with a 7 1/2' dugout cedar tub that I made), therefore I understand quite well the needs for, and am able to

visualize what could be used to improve usage or comfort in boating

design/rigging. I am probably considerably different than most fishermen in that if a product or accessory

is not available, I have the ability to fabricate it (or know someone who does),

as in my previous life I was a plant maintenance man and machinist. Then in my 20 plus years

of retirement, I still own a pretty well equipped machine and carpenter shop. While other

boaters or fishermen accept how a boat is built, or rigged, I am able to design and fabricate

helpful improvements.

After doing a lot of looking for used boats, I had pretty much settled on a 16'

Smoker Craft Alaskan model. I have a friend who has fished one of these

alongside of me in the bays for years, so I was pretty well aware of what they were. These older boats are riveted, (not welded), but

are a lot better than older riveted aluminum Hewescraft boats I have owned in

the past. These joints between the sides and bottom appear to have a sandwiched in thin mastic seal

between them, along with a LOT of very close LARGE HEADED rivets, and

these hulls appear be made of a bit thicker material than the older Hewescraft.

Smokercraft's CEO who owns Sylvan has said, if Boeing rivets it's airplane wings, that

is good enough for us. They claim rivets allow for slight movement of

the hull, where welds can crack, on thinner material normally used on smaller

boats.

Looking at numerous boats online and relatively close to my residence

(100 miles), I also found some Sylvans pop

up, (more than Smoker Crafts). Well it just happens that they are both made by the same company. My guess is

the Smoker Craft is the flagship line while the Sylvan being more of the utility

version, but the basic hull design appears pretty much the same (just a

different floor-plan). Of the

four

available near me, I selected an older 1994 Sylvan Yukon Select version, which has 81" beam with

21" freeboard, (quite a bit for a 16' boat with a fuel tank under the floor) and with an open floor plan (no cross seats).

This boat was

powered by a 2012 40hp Yamaha and a T series (high thrust) 8hp Yamaha 4 stroke

outboard motors. This was an older boat than the others I looked at, however it

appeared used but not really abused, with no dents or leaks. But

with all things considered, (including the galvanized trailer), what swayed

me more than anything was that it had a couple of newer, well known to be reliable motors,

than the other offerings. I had bought new and owned a Yamaha T8 for15 years (currently with 391 hours), which I just swapped onto this

new to me

boat, as I knew what condition it was in. Along with the fact that (1) I

was pushing a time frame to get this new boat to me on the water, chasing fall

Coho salmon. (2) Then on this T8 motor that was on the boat, had a extra long shaft, which

would be a detriment if back trolling shallow river tail-outs. However the

deeper saltwater it would be no

problem, maybe even a benefit.

I may miss the convertible top cabin of the North River if the weather turns

sour, however in my older years, in all possibility, I will not be on the water

much under those conditions anyway. But then that is what rain gear was

made for.

I later did minor work on this other T8 that I removed, and placed it onto my

North River, replacing my own, then put it up for sale (the North River).

Anchor System ; This boat was

obviously originally set up for Columbia River

spring/fall Chinook and sturgeon fishing, evidenced by the Columbia

River type anchor system installed on it. This entails a rocker type anchor

securely mounted in a holder on the bow. The latest owner

apparently had little interest in this type of fishing, (being an Asian)

as he targeted crappie at night on the lower

Snake River, or an occasional crab outing on the lower Columbia River.

| Here you see the Columbia River anchor from above | Here you see the Columbia River anchor from the front, also visible are the bow/docking lights |

|

|

These Columbia River anchor systems (which this one entailed an18# rocker type anchor) consisted of 140 feet of 3/8" anchor line which was contained in a 5 gallon plastic bucket. Since this takes up considerable room along with the 15" puller float, this long of a line will not be utilized very often, it has been replaced by a 3 gallon bucket which contains 75 feet of 7/16" nylon rappelling line and a 15# mushroom anchor. On these systems, the anchor itself is not attached until it is decided which type of fishing will be done that day, so an simple exchange of buckets which works quite well here. As my anticipated usage will not be using the float anchor puller possibly 95% of the time.

|

Here you see the large anchor line bucket

with the retrieval float |

Here you see the small anchor line bucket |

|

|

Again this boat was structurally sound, however maybe needing

a refresher paint job somewhere down the road.

It also came with a fitted canvas cover (which I may use) but the a Bimini top (I probably will never use). The Bimini tops I have been exposed to are not conducive to the type of fishing that I do, especially if they are extended, mainly they hinder usage unless folded back, but then why have them installed anyway if the bulk of your fishing is where they bare not needed? As they are not conducive to boarding the boat or fishing from the sides. They are essentially sun shades and not very useful in stormy weather.

Seating / Storage;

The two side seats were mounted on 3/4" plywood lids of the aluminum storage box

bases underneath, however the

wooden lids had deteriorated slightly to

where the hinge screws were loose. To make matters worse regular steel

nuts were used on the stainless bolts, which the nuts were so rusted that they had to be cut off with a Dremel

tool. The sliding rail for the seats were dinged, loose and corroded which

needed cleaning and a slight amount of grease added in the slider slot.

Then to retain these seats from sliding off the end of the rails, I drilled a

hole in the rail (on each side of the seat) and dropped a round headed screw in as a stop.

There is a moderate amount of storage under the side seats, with

plenty of room here for a large plastic waterproof toolbox and another with the

USCG safety components, plus a First Aid Kit and a few spare parts on the

Starboard skipper's side. On the Port side, I will use it for

storage of personal inflatable life vests, extra rod holders and

large plastic fish bags, even a spare prop. This box can also large enough

to accommodate fishing partners small tackle

bags, rain coats or lunch bags.

| Here you see the underside of the skippers seat with the waterproof safety & toolbox storage underneath | Here, the Port seat storage |

|

|

There is lots

of storage in the bow semi raised area

where a live-well could have occupied in the flagship line. This area has lots of

full width storage 16" deep at the keel and 23" forward/aft with a plastic cover and an actual opening of 9 1/2" X 19". Here are

stored extra life preservers, rain

gear, wool blankets, a couple of coats, collapsible paddles, etc.

| Here you see the storage in the location of what would have been a live-well |

|

Farther forward there is minimal bow storage, but mostly for the removable front bow navigation light.

At the rear sides, about

7" wide by 3

1/2' forward of transom inward and up near the gunnel, is a aluminum protrusion inward

side panel that also houses

rear side flotation, here the top cover has a

shallow 1" lip for a somewhat universal temporary catchall tray, and where

downrigger bases can be mounted in the forward section. This tray can also be the

location to keep the boat hook, mini gff hook etc.

As a note here, USCG

requires any boat 19' and shorter has to have full floatation. There is

flotation foam in the floor and these rear side panels also, which were probably needed to

have it meet these specs.

Catch Alls ;

I seem to have an affliction for "Catch All" provisions on my boats, which it had none real close to the fishing area that I like for

use of temporary fishing

gear type storage (changing terminal tackle, sinkers, etc.). However at the rear, I had already added a leader spool holder centered on the

forward lip of the splash well. This spool base now also forms a base for a 2 1/2" deep

by 7" X 10" wide 1/16" thick aluminum tray.

This tray sets in/on the leader spool base and is held in place by the 3/4"

wood dowel of the 1 1/2" dia. pipe insulation leader/hook foam. It (the tray) protrudes forward about

5" but

does not interfere with anything because directly below it is the forward

sloping door for entrance into the bilge that's footprint is forward of the

tray's front edge. This is not a true rectangular box, but the front two

corners have a1" wide 45 degree corner strip so that it does not have a sharp front corner in

case someone falls on it.

This tray was a challenge to bend, using only a carpenters square, sharpie felt pen, wood cutting bandsaw, large 6" machinists vise, a large rubber mallet and a pair of pliers. Then when formed, the other challenge was to get the holes for the retainer dowel aligned almost perfectly with the side holes in the base, as I wanted this tray as snug as possible. This was accomplished by placing it in desired location, using a sharpie felt pen to copy/draw the base hole, hand drill a 3/8" hole in the center, then using a Dremel tool and small cutter to remove most of the hole. Then install the tray and using a medium 1/2 round file, enlarge this hole to match the base hole, which took a lot of trial and error. Once finished, I had the corners TIG welded, and then rubber edge molding installed on the upper edges for a protective edging.

|

Here you see the unfinished leader spool/catchall tray |

Here you see the finished leader spool/catchall tray |

|

|

In the photos above if you are wondering what the white 3/4" PVC

pipe is, it has a Tee about in the center with 8" long downward protrusion, which fits into a Starboard rear rod holder and is a platform to support a salmon landing

net (providing an uncluttered support area) for when I am fishing solo and doing my own netting.

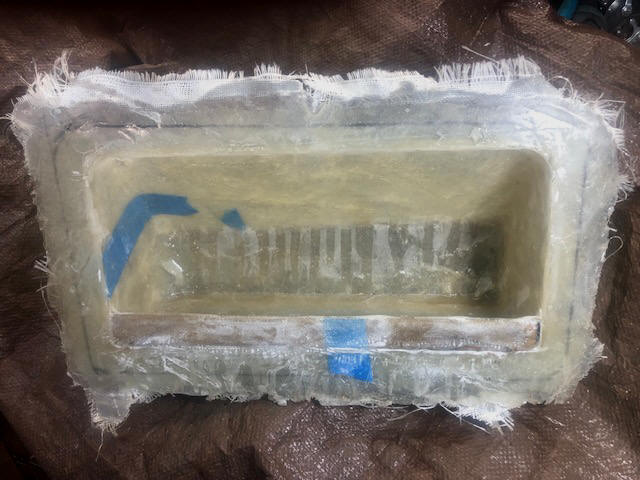

Side Storage ; One of the last major additions done on this fishing machine, I made a wooden male pattern to be used in making rear side storage pockets/trays. There was a hole on the Starboard rear panel that the old instrument panel used to call home. I had looked for a manufactured pocket storage units, but none were the size that I could use (to lARGE), OR within my budget. Why not just make a fiberglass storage insert to provide more storage AND cover up this hole in the side panel, killing two birds with one stone. These pockets are 14" long, 5" deep and 6 1/2" tall. They have a 1" front lip. While making one, might as well make a second one for the other side also. These will provide space for my scent bottle container and possibly my tether. I can also use these for keeping the fillet knife, hook sharpening file, hand wipe rag storage among other things that I am sure will crawl into them. In the RH photo below you are looking at the outer fiberglass cloth overlaid still on the male mold. This side will be later become the inner side of this tray.

| Here you see the old hole where the instrument panel was | Here you see the new side storage tray being made over the wood pattern |

|

|

In the LH photo below, you see the fiberglass tray removed from the mold and the

3/4" wooden lip in place. This fiberglass is now only 2-3 layers thick.

There was another 2 or 3 more layers of fiberglass and resin added, but on the

inside, and then the outer lip trimmed as marked.

The RH photo shows the finished tray in place (pop riveted) onto the boat.

The floatation foam was trimmed to fit, glued in place and reinstalled before

the tray was installed.

| Here you see the new side storage tray removed from the mold & the front lip in place | Here you see the finished tray & scent bottle container installed |

|

|

Then after I got catchall storages for me, maybe had better consider my passengers. So on the passenger (Port side) on the upper rear seat base, I made and installed a 2" X 2" X 14" aluminum tray which was pop rived to the aluminum seat box. This tray is out of the way but should provide enough catchall storage the guy in that seat to keep small tackle off the floor. Then while making trays, I also made another small 1" tray to go beside the skippers seat shelf between the seat and hull. Again both of these are fitted with rubber edge molding" to cover up any sharp edges.

| Here you see the port seat tray | Here you see the smaller skippers tray |

|

|

Moorage Cleats ; It also DID NOT have any side mooring cleats amidships or

on the stern. Which are

critical for when fishing solo, like when leaving the boat tied up to the dock while

parking/retrieving the trailer. Here, I

also use the rear cleat that is offside of the trolling motor to secure the fish

bleeding rope.

Then when I was up under the bow deck to rewire the navigation and docking bow lights I found something rather disturbing, the large center bow mooring cleat did not have any backing plates under the plywood, NOR did they have any nuts on it's retainer bolts either. The front side cleats were installed with just wood screws, (non stainless) as they are so close to the gunnel that there is no way to get nuts on any bolts there. Obviously not to be used for using tied to moorage and left for any length of time, but maybe Okay for securing bumpers.

| Here you see it underway |

|

Motors ; Normally, I sit on a swivel chair at the rear to steer

the trolling motor using it's tiller, just something I have done for many years

(I like to see where I am going not where I have been). However at times it can be beneficial to steer the smaller

trolling motor from the helm. This was accomplished by welding a 3/8" stainless

steel nut to the main motor's cable linkage bar as seen in the photo below.

This connector rod has a quick disconnect tie bar to be connected from the 8hp to the 40hp,

which will also allow either motor to be raised without removing the tie bar.

And this connector rod can readily be disconnected from both.

And I found out that for a lot of salmon trolling, this 40 hp motor idles

down quite well, so it can also be used if conditions are right.

I have also installed hour meters on both motors, which will help me keep track of run time, and for oil changes. These are the simple little black box with a wire running to be wrapped around a spark plug wire.

Guess what, if you are thinking about doing any of your own maintenance, even

changing the spark plugs on the 40 hp, you will need a special 18mm thin wall deep socket, and I

suggest it being a 3/8" drive. You will also need a short 2" extension,

along with

a universal joint, especially to access for the bottom plug. A suggestion is when

replacing these spark plugs, start them in the threads by hand to ensure you DO NOT get them

cross-threaded. Then the bottom plug has a tendency to fall out of

the socket upon removal of you are not careful (because of the universal joint) and is about impossible to retrieve by hand, where a

long handled magnet or a fingered pickup tool which is a great help. And if you are thinking of checking

compression, these spark plug threads are 12mm (more the size of motorcycles), not the

more standard 14mm.

Then the propeller shaft nut is 22mm (or 7/8"), why not use

this socket the same

3/8 drive, and use the 3/8" ratchet needed for the spark plugs? Here a

regular socket is Okay, not needing a deep socket as normally required on some

motors. Then under the prop nut is a fiber washer about 5/16" thick

that has splines to match the prop hub (12 splines), Behind this fiber

washer and under the prop nut is a stainless steel flat washer.

Sometimes this washer remembers it' early days a a track runner and remember it

is round. In case you cannot find it, the hole size is minimal of .650

with the outside diameter 1.400 diameter.

Power Tilt ; One thing that I was strongly considering later on

in this endeavor was, is to add a

power tilt conversion to the 40 hp motor. This motor currently is manual

tilt, but is designed so that the nitrogen shock (that lets it down slower, or

locks it in any position) can easily be replaced with a power unit. And if I am to run shallower river

water, it may be VERY BENEFICIAL to be able to lift the lower unit up at times

by simply

pushing a button. Then when about all the other modifications were

finished, I did purchase and installed a new electric hydraulic tilt conversion.

However I took it to a marine repair shop for the final electricals as this non power tilt motor

needed electrical up/down relays, so I just let them supply and finish that

installation (at a parts price shock).

The 8hp already has this as it was designed with it's own power tilt.

| Here you see a tie bar from the main motor's steering cable system to the trolling motor | |

|

Prop Guards ; Looking at the chewed up prop on the motor (and the 2 spares that the previous owner gifted me), made me consider some kind of prop guard. I may never run the same water as the previous owner, BUT I do not want this motor to revert back to her violent past. I had my welder friend weld up the bad prop dings, and I refinished the surfaces and repainted them, one to use, and the others as a spare.

And the

areas that I plan on frequenting can have sand/gravel bars and possibly even logs. Okay,

online I saw the Hydro-Shield product which looked interesting. I had the

ability, so I somewhat copied this idea, but made

mine out of 3/16" aluminum instead of a composite. However this type of guard only attaches to

the skeg, not both the skeg AND the cavitation plate as others do. This 40 hp motor

has in it's past probably had a couple of the latter prop guards installed as

evidenced by all the holes. So before going to far, I had my welder

friend weld up the existing 3 holes in the skeg, as with me adding 3 more (which

would be near impossible to locate the new guard into accurately) it would look like

Swiss cheese and be weakened considerably.

This type of guard is different in that yes, it does protect the prop, but also

helps prevent porpising on rippling water and with these these

lighter/shallow bottom boats (in my case a 12 degree bottom) helps slipping on

corners at a higher speed might be beneficial.

In using only photos to give me estimated dimensions, I

forgot to add in the total OAL because I was looking topside of an arced part.

Thereby making it to short, like 12 5/16" for this wings. Okay, after a

trip or two, redo and had anther couple of wings made, (one spare) only this time 15 1/2"

tip to tip for the arced wing. Now I will use the smaller set to

install on the 1990 15 hp Johnson on the 14' StarCraft aluminum boat that I will

sell.

I also have a hoop type prop guard on the T8 trolling motor,

which I made years ago, copying a commercially made Macs, and made of stainless steel,

which works quite well keeping fishing line out of the prop. I

actually believe it also gives a better directional thrust.

| Here you | Here you see the prop guard for the trolling motor |

|

Fuel Tank ; This boat has a 17 gallon fiberglass under the floor fuel tank. Apparently the 8 hp trolling motor was added separately later, as it was not plumbed for it's own fuel line, where they shared a common fuel line, and the only way it could be ran was to disconnect the fuel line from the larger motor and use it on the smaller motor. That may be OKAY for trout or crappie fishing, but on larger faster moving water that I plan on exploring, if $hit happens, the almost immediate usage of the second motor can be a life saver. Hence, it is now plumbed one fuel line off the tank outlet for each motor. However there is no main water/fuel separator (not a lot of room there, but it has a fuel filter on the 40 hp.

Electric

Trolling Motor ; Then I just happen to have an older Minn Kota 45# thrust electric trolling

motor that I purchased years ago, that can be mounted on the Starboard side on the transom and yet be able to clear

the transducer. This should be helpful on a day somewhere in the future (like backtrolling

for Steelhead/drifting/casting spinners for river Coho). Here I run an extra 12 Volt marine battery for it's power as to not drain

my main power battery, leaving me stranded. This battery is secured

under the port splash tray by a bungee cord.

| Here you see the electric trolling motor |

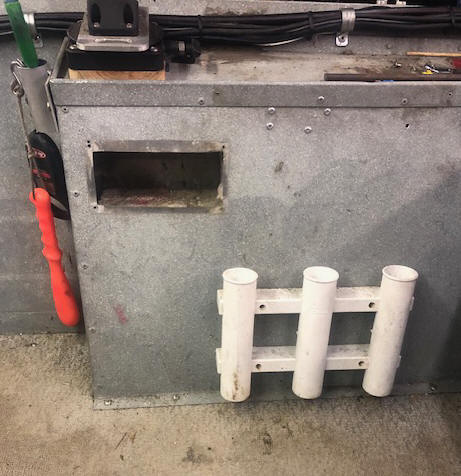

Batteries ; The under the rear splash well on the Starboard side is where the marine battery is located. here I installed a strip of aluminum angle in front of the battery as a securement for this battery.

However space is limited (partly because of the rod rack on the side in front of the battery) where this series 27 battery that came with the boat is too long to fit sideways under this well. Therefore this battery had to be inserted lengthwise, taking up room forward of this opening. Hence I purchased a series 24 shorter battery which can now be slid in sideways. I will retain the series 27 battery for usage with the Minn Kota electric trolling motor. I have also installed a main battery disconnect switch on eBay that was labeled as (car power main switch) and installed it on this main battery positive terminal, and with it pointing to the rear, tucked in pretty tight under the splash pan making it hard to see and/or decipher what it is. And this switch's knob works backwards to what you would think.

|

Here

you see the shut off switch on the battery |

|

There is a similar space on the Port side, but it is not as usable because the fuel tank filler hose and vent line takes up a lot of usable space there. In the center between these is a 20" wide hinged lid giving access to the bilge pump, fuel tank fittings and drain plug areas, but with no provision for lifting this lid, so I simply added a knob on the Port side, and a stick to prop it open.

| Here you see the battery compartment | Here the fuel line Tee to both motors with the fuel tank sender in the foreground with the bilge pump buried to the left of the center brace | Here you see the port compartment showing the fuel filler/ventlines |

|

|

|

Bilge Pump ;

In my

rewiring in the battery area for the bilge pump and fuel gauge, the

bilge pump was not attached to anything other that it's outlet hose, it

was just laying there on it's side in the bilge. Okay, while I was

there doing the rewiring, I might as well pull the pump out and make a

mounting bracket for it. When I got it out, there was a LOT of debris

in the bilge there, like sand, rocks, a conduit strap, bolts, nuts, a

glass fuse, and a unidentifiable small coin (probably a 1943 zinc

penny).

This pump motor can be rotated, allowing it to separate from the pump

body, giving access to the pump itself. WOW, lots of sand, so much that

my guess the pump, if it was operative, would possibly not have enough

force to even get any water overboard. And of course since it was so

old that the twist lock plastic retainer prongs broke off during

disassembly, which I did not notice until time to reinstall it. Good

old Duct Tape to the rescue again.

As

a note, is 6 1/2" between the bottom and the floor, so if any water was showing

above the floor, we would

be sluggish to respond and unable to get it up on a plane.

Since there is no wash-down pump on this boat, nor no

real room to install one, therefore I use a 1 gallon painters plastic bucket,

which I tie about 2' of 5/16" Nylon line with a large loop in the outer end as a

hand hold, which helps for dipping water and no loosing the bucket. This

bucket

can be stored in the rear movable seat tray which secures it out of the

way, yet readily available.

Console ; When I first got this boat and with extra more accessible small storage in mind, and I was installing a new instrument panel on the center side console, I hatched the idea of adding a inner shelf up under this console and down about 5" from its lower dash lip. However with the steering gearbox input cable, needing to have the shelf bottom cut out to accommodate this cable, it became obvious that a single bottom piece would be impossible to fit in, so I cut it in two, and with careful fitting after making cardboard templates made it fit. This shelf is not permanently installed just in case the steering cable may need to be replaced. This shelf is pretty well protected by the upper part of the console and will provide storage for the boat and trailer registration, a spare key, battery voltage tester, binoculars, flash light, sling shot and lead balls, fishing regs, cell phone, candy bars (I managed to get 20 KitKat snack size chocolate candy bars in a bulk seasoning plastic jar).

This registration/key container is simply a plastic Skippers cocktail

sauce jar with the lid screwed up under the inside of the console, making it waterproof, compact

and out of the way.

The fire extinguisher was relocated to the front starboard

corner of the console, out of the way but ready.

Then in the new vertical dual rod rack on the console,

in between the holders was a built-in knife holder, where I store my heavy duty

fillet knife. This is not the normal fillet knife, but a stainless steel

butcher knife with a blade of 10", as when filleting salmon, we cut all the rib bones off the

backbone, and then later fillet these bones out, therefore you need a sturdier

knife than a normal fillet knife.

| Here you see the console from inside with the self just showing |

Here you see

the console from outside, note the 0000 horn on the outside of the console |

|

|

One thing to remember on boat building/rebuilding, NOTHING is square or level, however possibly parallel to the floor.

Electrical Wiring - Or Lack Of ; I quickly found (at least one) of a previous owner's mechanical/electrical inability was less than minimal. As almost all the wiring needs to be completely redone, because it all (other than the motor itself) from the rear side mounted instrument panel to the battery had been cut off under the splashwell near the transom. Originally this boat had a small switch/instrument panel on the starboard rear side panel. However as mentioned above, all the wiring was cut off under the splash well. This panel was an exact copy of a friend's Smoker Craft of near the same year and size as this boat, which both had 4 rocker switches with circuit breakers, power from the panel/gas gauge, bilge pump, lights, live well (however it has no live well).

I tired to trace out the cut wiring but finally just gave up as it seemed that possibly some of the switches or resets may have been defective or shorted out and on3e fed power to all, that may be why they just cut them all. This then gave me the opportunity, AND incentive to make a new instrument panel, and moving it forward into the console's dash.

When I took delivery of it, the bilge pump was activated by 2 alligator clamps

onto the battery. The economy sonar was also using another set of

alligator clamps for it's power.

OKAY, time for a complete rewiring job. Here I used the old gas

gauge, added a tachometer and 4 new toggle switches. To facilitate pulling new

wiring from the rear battery area to the console, I drilled a

1/2" hole at the very rear of the starboard side floatation panel and managed to run

a long welding rod fish-tape with a slight bend on the lower end down behind the

foam, and

managed to get it out the hole

below where the original wires had went through. Great, now I was

able to pull 4 new wires inside that side panel from the battery area, up along the Starboard gunnel

with the rest of the controls up and into the console. From this, I

was able to run a positive and a ground wire (negative) to the new panel, while the other

two wires were for the gas gauge and bilge pumps. The tachometer would then be wired into the

Yamaha harness at the throttle/shifting control.

Update on the fuel gauge, Initially this old gauge did not work on

the new instrument panel. Okay, I ordered a new gauge and matching sender

unit. But I could not get it to read anywhere near the full tank that it

was.

I tried so many things, but finally gave up and reverted back to the old system.

The only difference this time was I also grounded the gauge itself because of the

plastic panel (as the new gauge instructions showed). The old gauge's wiring

had one ground wire that was cut, which (unknown to me) must have went to the to this gauge

ground (mounting bolt). It now works. What I found on the newer system, it was made

to be universal, and more toward larger/deeper tanks. This17 gallon

tank was only 5

1/2" deep, which when the float was fitted, it could not have the needed full float

arm movement to do a even somewhat accurate reading. And trying the old sender unit with the new gauge only

showed 3/8 full, because these systems use a resistance to register the correct

reading, therefore these two were not compatible. Lots of time wasted and

MANY trips in and out of the boat.

The main power switch in the console uses a inline 10 Amp spade fuse

on it's outlet wire, and it's wires are long enough that this holder can be

withdrawn enough from under the dash for the fuse to now be

replaced without removing the instrument panel. To facilitate finding it

up underneath, a short cord attached to a foam key fob makes it more

identifiable and accessible.

This wiring is not what I like to see because of the limited

space up under this dash, it would be about impossible to use a fuse block with

individual fuses as there is not enough room for access. To do it this

way, the only way

would be to prewire it on a board, then attach the board inside/under the dash,

Then the issue would be if a fuse would blow, it would be near impossible to replace

it without removing the instrument panel (6 screws), and also near impossible to even

identify which fuse was blown because of the limited access. What I

have done was to identify (label) each hot wire (red or white) going to a

cluster at a large red wire nut. For the ground, all wires are black

and again using a wire nut, but green. These wires are not neat,

but just poked in with some semblance of necessity to hide them up and under

this dash and out of the way as much as possible.

On wiring the instrument panel, I have four toggle switches.

each operating (1) main power to dash, (2) bilge pump, (3) navigation

lights, (4) docking or bow lights. There is a blue indicator light above

main on switch and green for both the bilge pump and bow lights.

Here is an experience that I am hesitant to share.

In installing the 4 switches in the new instrument panel, I thought I had

positioned all of them with the OFF position was UP. When I got all the

wires ran to the switches, I could not get power when I turned on the main

switch. I fought that for maybe 2 days, then finally ran a jumper wire

from the battery to the panel. Ground wire made no difference, then when I

ran the hot wire jumper, it was hot. I figured the new hot wire was

possibly defective. So I cut all the zip-ties on this wiring bundle, pulled the

(bad) hot wire and shorted it to the battery. SPARK. It was Okay ???

I pulled it back into the panel, connected all the hot wires using a (temporary)

electrical wire nut. Got power to the Sonar. What had gone wrong?

Had that input hot wire not made good contact in the wire nut connecter? Then I

noticed my main power switch on the panel was positioned in the OFF position.

What I had done was not positioned it (the switch) in the same orientation as the others.

I had the wiring right for 2 days, but was flipping this main power switch to OFF,

thinking I was turning it ON.

One of the hardest wiring parts was to rewire up under the small bow deck. Who ever did this must have been a triple elbowed midget, (as the access was through a 7 1/2" X 11" rear facing hatch). Then to compound the issue, the wires were cut short. Trying to reach in at arms length, with minimal lighting, trying to connect these short 3 wires into a electrical wire nut by feel was conducive to muttering a few fowl words. Here the previous owner had installed bow/docking lights, but he had wired them into and in conjunction with the navigation lights, something I was not happy with. So I had to run a second set of wires and an individual switch for them.

Among the things that I also added to this console was a USB cell phone charger

outlet. This can also be used to recharge my VHF handheld radio.

I also added a CB/VHF hanging clip for

the handheld VHF radio on the dash just left of the steering wheel, so it will

be secure and readily accessible.

And it just so happens that my large fishing tackle box just fits under

this console, leaving the floor more open and uncluttered.

I also added a small wooden base made from 2" X 4" wood which a 1

1/2" hole was drilled 90% through to allow a mini size Freon horn a home,

screwing it onto the outer side of the console. Also in that area,

near the throttle/shifting controls and front on the seat base,

but out of the way, I added a cup holder.

Sonar/GPS ;

Here I was gifted two Lowrance units, an older HDS 5 that was off a live

aboard sailboat had never been

updated, and a newer uploaded, HDS 7 Gen 2 where the previous owner upgraded to a

new style Garman, which is the one I had picked for this boat. It took me a while of being in brain fog, initially I

was concentrating to transferring the data off my North River's HDS 7, then it hit me, why

not just swap these units. This way I have all my old data without

the bother of transferring, and the new owner when I sell that boat to may not fish the areas I had.

And for my newer type of fishing, I will probably set the shallow

water alarm at 3'.

| Here you see the finished console. Notice the shelf underneath |

|

Fish Box ; And there were no provisions for a fish-box of any

kind. So in my looking for a fish-box, I found that a Coleman 70 quart cooler

which fit

pretty well on the forward semi-deck up against the shorter bow deck. This is held in

place by a long bungee cord around the upper section and between some aluminum angle

on the forward deck to help it's sideways stability. It can also be

used as a seat for someone if need be.

Throwable Life Preservers ; Then to be in USCG compliance, each boat has to have a throwable life cushion/preserver readily available. Okay, why not place one on the rear side of the cooler and use the bungee cord to hold it in place also? This would make it out of the way and about as readily available as possible.

In the photo below, you can see the fish-box cooler/required cushion, rear view of the Columbia River anchor which is attached to the bow. And the rear of the (black) docking bow lights.

| Here you see the fish-box / throw cushion |

|

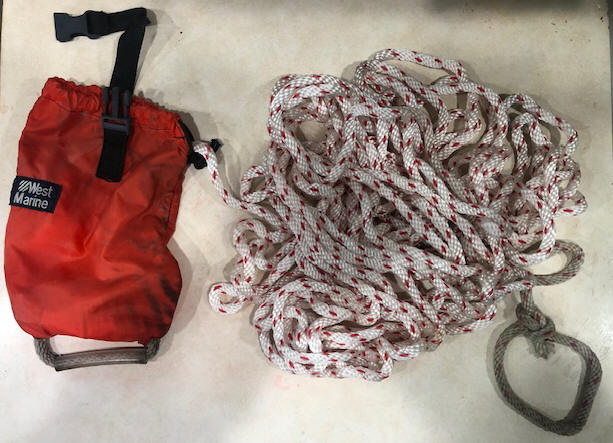

Then later I remembered that on my North River boat, I had a better throw line,

which I snatched for that boat.

This

is a 'Rescue Throw Rope' sold by West Marine.

It comes all contained in a small Nylon bag,

stuffed with 50 feet of 3/8" rope with a small float inside and secured

using a draw string with a spring loaded lock. Also on

this float bag is a handle, for use for a grab handle if you are throwing it to a person in the

water. The

protruding rope end has a loop that you slip over your wrist (preferably your

non throwing hand). You throw it underhanded like throwing horseshoes.

It is heavy enough making it easier/more accurate to throw, AND

retrievable.

In the photos below the black strap is a 1" Nylon strap which uses

a standard push button Nylon strap buckle. This is so you can attach

it to a convertible boat top frame or whatever, for quick usage and use it for a

throw handle.

| Here you see a rescue throw rope bag |

Here you see a rescue throw rope bag with

the rope exposed |

|

|

One thing when you re-stuff the rope back into these throw bags, be sure that you straighten out the loops or possible knots.

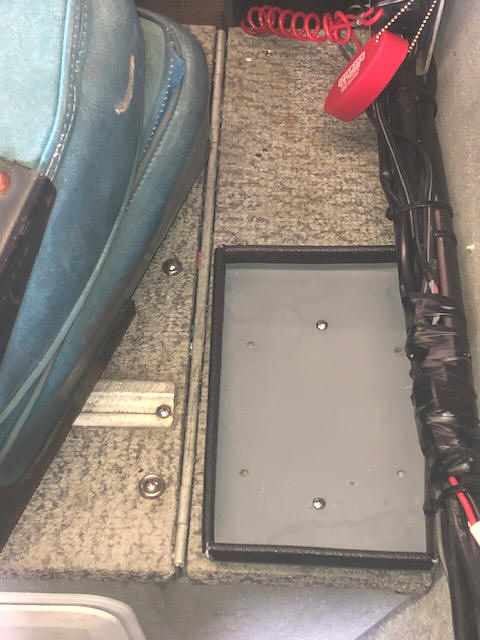

Swivel Chair ; The rear swivel seat was originally stationary, which I removed and

attached this folding seat (seen below) onto a swivel base 4 legged chair that was designed

for this. In doing this it left a 3" hole in the floor. On

the opposite side there was a 5" plastic cover the same hole where this

seat could have been installed on the starboard side. I copied a

plywood cover off the plastic one. Then later I found two

other plastic covers under the mid seat boxes, which I simply swapped

out for the plywood one.

On my previous swivel chairs, I have welded a 3/4" angle iron frame onto the legs up about 5 ", and installed a stainless or aluminum expanded metal bottom, so that no water would accumulate. This also is again a close catch-all during fishing. Needless to say I did the same to this chair base.

| Here you see the new swivel chair catch-all tray |

|

In the photo below you see the inner rear parts of this boat,

with the center hinged lid raised for access to the bilge pump and fuel gauge

sender. The series 24M marine battery is on the left. On the right is the fuel

line filler and vent hoses.

| Here you see the transom area with the motors and with the center lid raised |

|

Rod Holders ;

Here, the rod holders were not placed in convenient

locations for my type of fishing, or if they were, they were

scantily secured. The Fish-On bases were possibly mounted fine for trout fishing at anchor, but

woefully in wrong places for salmon trolling. And most of them were

only retained by two self-tapping #14 screws into the gunnel. I solved

that by securing them with all (4) 1/4" stainless steel bolts and nuts. I had lucked out

at a yard sale a few weeks before, purchasing 3 sets of these same rod holders (complete with

bases) for $6.00 total. They normally sell for about $25 for each

set.

This boat came with a triple vertical rod rack mounted on the starboard inner rear panel rearward and below the old instrument pane, which I tried to remove and reinstall forward on the inner side of the console, but it was SECURELY glued in place, so I left it there, but found a dual rack for that forward installation.

| Rod holders |

Downriggers ;

There were bases of a unknown brand for downriggers installed, which were mounted in the rear

side shelf, but not enough forward for the fisherperson to stand

rearward of them to operate effectively. I had let my Scotty electric model

downriggers go with my larger boat when I sold it, but

I had picked up a couple

of used Scotty manual versions as backups, so these will find a home here when that time comes, as I

have installed bases to accommodate them.

For these bases, I have added Cannon low profile swivel plates under the

Scotty bases, which provides easy access to multi positioning the downrigger

in any position at deployment time or rotated rearward while landing a

fish or moving from

one location to the other. Here I had to add a 3/8" aluminum adapter

plate between the two, to accomplish this.

| Here you see one of the manual downriggers mounted. Note my nylon tether in the slot of the base adapter | Here you see the tether attachment welded onto the downrigger adapter base |

|

|

I always wear an "Offshore" inflatable life vest when I am on the water.

These vests have double Dee rings (one on each side) in front where, when

fishing alone, I snap a 10' Nylon web strap which has a quick release onto

these Dee rings. As an afterthought, I then made a shallow 1/4" aluminum U shaped anchor point that

was welded onto this downrigger aluminum adapter plates, (as seen in the RH

photo above) that will be my tether anchor to

the boat, as seen in the above photo. This way it (this anchor slot) is out of

the way, permanent and can be

used even if the downrigger was being used.

Launching Solo ;

When launching solo, there are issues that are completely different than with a

partner. Who holds onto your bow line at launch time? I have developed a

method where my bow line is at least 6' longer than the trailer. I have

installed a larger mooring cleat to the trailer winch upright, to which I attach

the bow line to at launch time. Here, after removing the winch hook, I back down the ramp,

remove the trailer safety chain, back farther, submerging the boat enough to where most of it is

floating, keep backing a bit more, hit the brakes and float the boat off the trailer.

Now I gently pull ahead, taking up the slack in this bow line which of course is also

attached to the bow of the boat. As the floating boat reaches the end of the line, the boat

stops it's rearward motion and follows the trailer back to the waters edge of

the launch like

a well trained puppy. I can then secure it (the boat) to the bank (with a

small river anchor) or tie it to the dock

and drive up and to park the trailer.

One thing that I found was THIS bow line was NEW 3/8" hollow

core Polypropylene, of which you can open up the weave and insert the tail of the

eye into the hollow weave, which then acts as a Chinese finger stall, making a

neat eye splice. However this particular line was stiff enough (or

the weather was cooler) that

it did not grip the tail well enough (being so new) so that under strain, the eye pulled out.

Luckily not before it had stopped the rearward motion of the boat and started it

back slowly toward the launch. My remedy was to use a couple of small Zip ties

into and through both the inner and outer parts of the line, securing the eye

better.

|

Here you see the solo bow line retainer

cleat with the white line attached to it |

|

|

The Trailer ;

The trailer's passenger side had been backed into and the

taillight assembly was held in place by a small dia. cord. And it's

metal mounting bracket was badly bent. Along with the boat was sitting too far

forward by possibly 5", (either caused by this accident or power loading) to where the winch mount

needed to be repositioned rearward. At this time, I also relocated the tongue

mounted crank farther forward of the winch mount.

With this repositioning, I now mounted on the port side of

the tongue a 6" X 34" aluminum expanded metal catwalk that I had salvaged

from a scrap bin. This was attached to the tongue using existing bolts

that secure the winch support and the spare tire bracket on the front

and middle. There had to be a front support brace installed

but fabricated to clear the tongue jack when it was folded back for

traveling. The rear section lays on top of the trailer side frame

and is bolted to it. This can be used to help in loading if need

be.

| Here you see the trailer catwalk |

|

The rear bunk side loading guides were short and rather low, creating a loading

issue if in a cross wind or tidal current if the trailer happens to be

a little to deep in the water. Some guides are 3 times this long,

depending on the boat or trailer involved. These were a single

mount on the rear trailer cross-frame and were guide pas was only 26" long.

After sleeping on finding a solution, I decided to simply raise the

guides by adding a spacer between the base and the guides. In

searching for a metal, I found a scrap 3/16" X 18" aluminum plate that I

was able to make two 7" high plates, which raised the guides by 5".

But the base was not at a

true perpendicular angle for some reason, (tipped outward a bout 10

degrees) so I had to add a slight bend

in these plates pulling the guide closer to the boat to compensate, this method was a lot easier than

removing and bending these

bolt on bases.

These guides are especially useful when loading at a launch where there is no

dock, and Or with a current or wind blowing. In use with the trailer backed into the water, usually with

the fenders 3" showing about above the water. When bucking a wind or

current, it is about impossible to power load coming in straight onto

the trailer. You have to compensate for the wind, this is

done by coming in from downstream

at a angle, then turn onto and straight with the trailer (timing is

critical, not an easy

task). With these higher side guides, you slowly nose the bow into the wind and inward against the

upstream guide. Ease in with little power against this side guide

which allows you to then pivot the boat's bow more in line with the trailer,

and then when more aligned, add some power to partly load.

If you find the right combination, these guides effectively guide the boat more aligned onto the

trailer. Once it is straighter, more power and you can run

it up farther forward, even into the trailer bow Vee nest. If you need to straighten it a bit

at the rear, just use the

motor to compensate slightly pivoting the stern on the trailer, centering it,

more power and into the Vee on the winch stand. Then you can get

off the boat, attach the winch hook to the boat's bow eye and tighten it

into the Vee, attach your safety chain and drive up the ramp.

After using this boat in launching/recovering at both a dock

and a river (where the current was running) these extended guides help

tremendously.

| Here you see the new raised trailer side bunk guides |

|

Then when I was checking the tires for air pressure, I found

that the spare tire had no valve stem core. So it would have been

completely flat if it was needed.

Then the wheel bearing covers were just that (just the "dust cover" type on it) are not "Bearing Buddy" type which are way better in lubricating the bearings. Time to look at the bearings and at the same time adding the Bearing Buddys that I just happened to have a used set.

In checking the wheel bearings, something else became apparent. The left fender (plastic) inner side had a hole worn through about 4" X 8" long and the hubs were new (made in China). Looking farther the axle had also been replaced. It became obvious that at some time in it's previous life a axle bearing wore out enough that the inner bearing/hub had been ran enough to ruin the spindle. The new black painted axle has no rust on it like the springs did. These bearings looked like they had just been replaced, but with minimal grease packing, so in all probability the whole axle with bearings and hubs were replaced in the not so distant past. And the axle is not centered as the right tire protrudes 2" beyond it's fender, while the other tire is 1" inward.

The rims needed a paint

job, along with one was a odd-ball, so it is now the spare.

Guess what, the old spare that was missing the valve stem core, (which I

replaced) well

that was not all that was wrong, after airing it up and now on a wheel,

it was flat again a week later. Time to head for a tire shop before a flat

happens on

the road.

When I got it to the tire shop it was still swished flat on

one side, and when they aired it up, they could not find any leaks ????

This tire is brand new, as it still has the small rubber needles

protruding on the tread along with a blue stripe around the center of

the tread. It matches the other two tires so apparently all three were

replaced at the same time. The ones on the axle have not

been ran a lot as they still have LOTS of tread.

As a FYI on repainting the rims, instead of masking off the tires, I

found an old lampshade, cut it off so there was about 3" left on the

lower edge, which allowed me to fit it on the tire outside of the rim,

where I could get a good paint coverage with no overspray.

And during this trailer repair, I found that the lights are

sealed beam, which is a good thing.

So needless to say it took me more than a couple of weeks, repairing and

remodeling before I got it close to getting it wet, and even before I got the

registration changed.

Shakedown Cruse ;

OKAY, 2 1/2 weeks of remodeling/fixing, I finally had it fishable enough

for a shakedown cruse.

I am pretty happy with the outcome, however we did find a few modifications

were needed (like the one rod holder that I had not moved), really needs to be

moved forward enough to accommodate the tiller handle of the T8 trolling motor.

This main motor had no out of the hole power, as the previous owner was looking for speed, where I am looking for utility, so his highly pitched prop will have to go.

His sonar would not function, even though I had tried it previously, (possibly a

bad/broken wire at the alligator battery clamp) so time to

replace it with the Lowrance HDS7, off my North River boat.

And on this trip, we had what appears to be a intermittent lack of

fuel supply issue on the main motor. squeezing/pumping the primer bulb while this

was happening did nothing,

indicating the fuel pump was probably not the issue. But when I got it

home, I removed the onboard fuel filter, which did not look really that bad, but I

ordered two off eBay (for $10.49) and have now installed one. I begin to

wonder if that may be what the previous owner sold the boat, thinking the motor

was going bad.

And I even caught a Coho salmon on this trip.

Second Trip ;

OKAY another month had passed.

Needless to say, this boat took a lot more work

on than I had expected. OR maybe I am getting older to where I need

frequent rests. However I am told that I am a perfectionist and do not do

anything only half done. And repairs like this seems to be something that I do enjoy,

being able to finding an issue, and then being able to solve it, along with it keeps me

busy. And at my age, the chase seems just almost as important as the catch. I

just wish I had kept track of the number of times that I climbed aboard in

doing these repairs.

This second trip was more of a test run to verify the

starving for fuel issue with the main motor was just a plugged fuel filter

(which I had replaced). I took it to a nearby electrical power reservoir,

and gave it a 20 minute run. It ran at all speeds without any hiccups.

This partly convinced me that the previous owner was probably also having

starving issues also but had not thought (or knew) about the filter.

However what really

solidified this thought was I later remembered when I bought it, there was a new

fuel line coupler that he gave me, saying "you might be able to use this

sometime". That added to the rest that I now know has convinced me

he had issues and thought maybe the fuel line coupler to the motor may have been

sucking air also, especially when I primed the fuel filter (using the primer bulb), I

got a few drips of gas at this old coupler. He had possibly been

there, and again, very likely had been having this fuel issue also. I am now

pretty sure that is one reason that he sold the boat.

Thinking back, of all the boats that I have owned, VERY FEW

did not have some kind of an issue at the time of the purchase. And

here I

am not counting any improvements that I made afterwards.

I am very happy with the final results of this boat. It

handles like a dream, and for being 2 feet shorter, it actually has more fishing space than

my longer North River. There are a few things yet to get up and going, like the

fuel gauge and the tachometer, but it is now USCG compliant and totally fishable.

These other issues will be addressed during the winter. And I may pull the floor over the fuel tank and inspect it

as there are two unknown wires protruding from under it at the rear. Along with maybe adding

a small Plexiglas windshield to the console.

By now you have probably decided that I don't go part way in

rigging my boats and that it is important to have even small things operational. In

my boat repairs, all screws, bolts and nuts are stainless steel.

Some smart person once said "95% of successful fishing is done the night before". In my mind this also pertains to having your boat totally ready, "everything has a place, and in it's place".

Miscl & Other Helpful Things ; Here you will/have seen little things that I add to my boats which assist me during an outing. (1) As shown above the movable swivel chair with a catchall tray underneath. (2) A removable foam leader spool holder. (3) A removable aluminum catchall tray used in conjunction with #2. (4) A mini gaff type hook that is used to secure salmon after they are on the deck, and to carry them to the fishbox.

(5) A tuna cord fish bleeder line using a combo toggle arm on the lower end that also functions as a gill cutter as seen above on the right.

(6) Scent bottle holders.

(7) A push pad that attaches to the removable hook end of a extendable boat hook. Anyone who fishes the bays who says they never run aground is lying to you, just look at their props. This 2" X 4" wooden pad simply mounts on the boat hook threads. Beats climbing overboard.

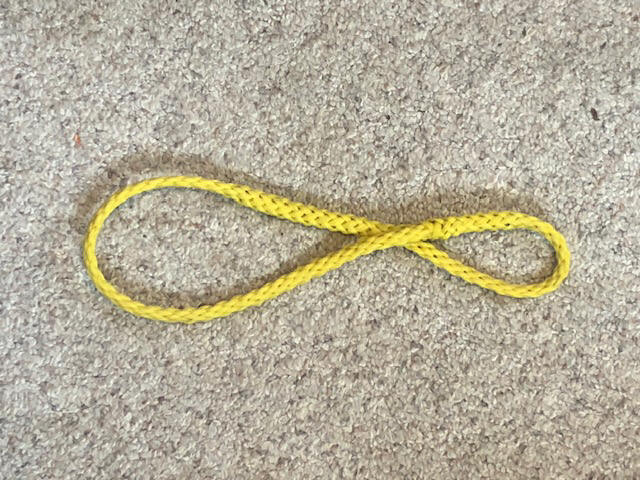

(8) Quick docking tether for mid mooring cleat. Here a simple figure eight slightly over 12" long with the small end to slip over and usually remain on your mid mooring cleat (of which side you will be tying up to at that time). The large loop is large enough to fit easily and quickly over most dock cleats. Just slip it over the dock cleat and you are tethered temporarily.

(9) A net minder for the landing net.

(10) salmon net cradle for use when netting solo.

After leaving the at the marine repair for over a month, in outside UNCOVERED storage, (I should have used the cover) I found that all the storage was VERY DISMAL in being waterproof. Everything got wet (however we had LOTS of rain during that time frame. I am going to have to see if on the forward deck storage to see if I can seal the deck to sidewall hull. And use smaller dry boxes. For the box seats, probably nothing other than, anything that could be damaged will have to be in tied bags. I will not get caught again in "OUT OF SIGHT - MIND". It also gave me incentive to use a waterproofing spray on the insulated Camo jackets and Nylon rain pants. And he left the ignition switch on, running the battery down.

| Here you see the reaults of over 5 months of tinkering |

Copyright © 2025 - 2026 LeeRoy Wisner

All Rights Reserved

Back to the Main Ramblings Page

Originated 08-30-2025, Last updated 02-06-2026