Winchester Post 64 Model 70

Information

POST 64 GUNS:

Gun production methods had changed to the

point that Olin had to look at just how they made this model as compared to how

Remington was making the model 700's. Winchester was making guns the "OLD

WAY" using many machines & multiple operations to complete each part.

Remington on the other hand had gained much from WWII production insight by

using stamped parts wherever possible & different design methods when they

introduced their new model 721 & 722 right after the war.

Winchester on the other hand was kind of stuck with the established & well thought of model 70, which did not lend itself with modernization without suffering dramatic cosmetic changes. The upper level management at Olin must have thought that they could convince the buying public that the newer models were just as good. Mechanically they were, but just try to convince the older generation that knew what they wanted, not what somebody thought they wanted.

This time frame also saw one of our greatest inflationary periods ever. Increased shortages of good walnut for stocks & the rise in cost of steel & other alloy materials. Raising demands for American skilled labor also was a contributing factor. Many extras that were offered before were dropped from the catalogs, probably because they had no one skilled enough to produce the extras.

One author stated that the existing tooling was wearing out. This may have been so to a point, but my thoughts are that the company needed to cut production costs to survive & the R & D crew was given a task. They did an admirable job while yet maintaining the somewhat resemblance of the predecessor.

Serial numbers were supposed to have started at 700,000 when the new model was introduced in1964. However a few have been noticed at numbers below that established guideline. Many things changed on this model as compared to just the year before. The most obvious was the impressed checkering & stock finish. The old Mauser type extractor was eliminated & a new style smaller unit was moved into the RH bolt lug & it used a spring loaded plungered system. The ejector was a small spring loaded plunger incorporated into the bottom front of the bolt face. There was a striker cap on the rear of the bolt sleeve covering the rear of the firing pin, serving as a gas deflector.

The sights were made by Williams Gunsight Co. as their standard replacement sights for gunsmiths that screwed onto the barrel. The action was lengthened slightly to accommodate the longer cartridges. The magazine boxes were stamped & utilized feed rails/lips instead of the receiver having to be machined for each cartridge. The trigger guard (guard bow as the factory calls it) was made from an aluminum casting that was painted black. The floorplate was a steel casting that was copper plated & then black chromed. The barrel used the same threads as before, but did not keep the coned breech.

The trigger & sear were a casting. The bolt handle was cast & silver braze welded onto the rear of the bolt body. There was no anti bind lug on the middle left side of the bolt body.

After the 1968 Federal gun control law, (put thru congress

after JF Kennedy was assassinated), all the Post 64 guns then carried a "G" s/n

prefix starting at near 874,000. This was also the time the

"Anti-Bind" bolt was initiated. This new bolt used a lip on the lower edge

of the RH locking lug. The lip rode under a part of the receiver rail that

help prevent bolt binding.

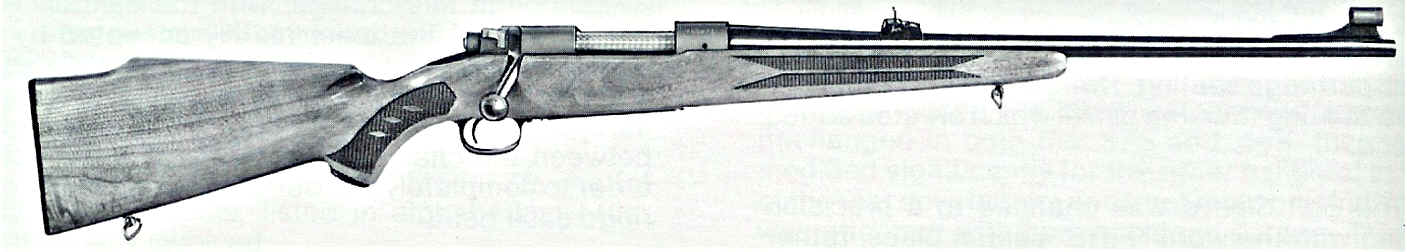

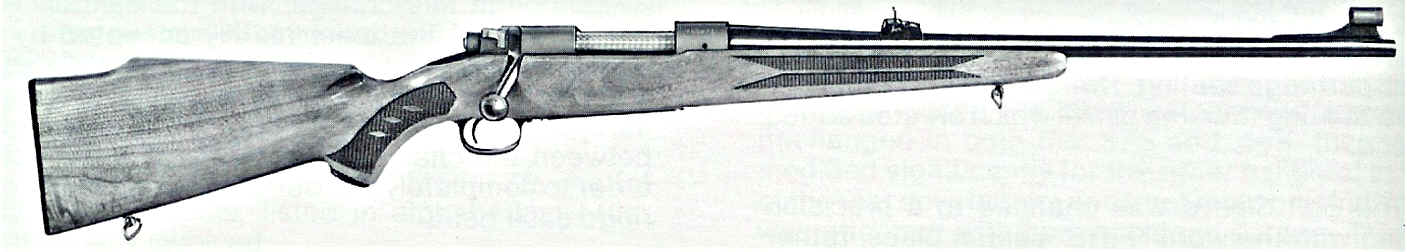

Over the years since 1964 this model has went thru many cosmetic changes.

These ranged from cheaper guns with blind magazines & walnut stained birch

stocks, to Mannlicher stocks, to hard finished walnut with machine cut

checkering. The list goes on which included 11 different styles.

The 670 was a blind magazine birch stocked version with a sliding side safety. Next was a 670A, which was basically the same but had the bolt sleeve mounted conventional M 70 pivoting safety. There was then the 770 & 70A which were basically the same same as the 670A except for a walnut stock. The 70A used the same barrel, stamped model 70, so those that did not know bragged they had a model 70 because that is what it said on the barrel & did it not have the hinged floorplate of the model 70.

Serial Numbers for date manufactured for post-64 guns

| Year | S/N start | S/N end | Quantity |

| 1964 | 700,000 | 757,180 | 57,181 |

| 1965 | 757,181 | 818,500 | 61,320 |

| 1966 | 818,501 | 855,860 | 37,360 |

| 1967 | 855,861 | 873,694 | 17,834 |

| 1968 | G873,695 | G929,990 | 56,296 |

|

1969 |

G929,991 | G965,200 | 35,210 |

| 1970 | G965,201 | G1,000,436 | 43,236 |

| 1971 | G1,000,437 | G1,041,884 | 33,448 |

| 1972 | G1,041,885 | G1,088,291 | 46,407 |

| 1973 | G1,088,292 | G1,130,146 | 41,855 |

| 1974 | G1,130,147 | G1,176,878 | 46,732 |

| 1975 | G1,176,879 | G1,235,041 | 58,163 |

| 1976 | G1,235,042 | G1,298,272 | 63,231 |

| 1977 | G1,298,273 | G1,380,667 | 82,395 |

| 1978 | G1,380,668 | G1,423,869 | 43,202 |

| 1979 | G1,423,870 | G1,450,135 | 26,266 |

| 1980 | G1,450,135 | G1,493,463 | 43,328 |

| 1981 | G1,493,464 | G1,525,323 | 31,860 |

Guns made after 1981 would have been made by USRA & not shown on this chart

USRAC:

USRAC (United States Repeating Arms Corp.) was formed and

continued manufacturing Winchester brand rifles and shotguns under license from

Olin Corp. on 7-20-1981. This final year of Olin production

saw a new "XTR Featherweight". But very few actually made it to the

dealers shelves before USRAC took over. The only way I have been able to

discern the difference is that the thin red/brown rubber Pachmayr buttplate would

have been the only difference displaying either the name "Winchester" or

"USRAC".

USRAC, which licenses the Winchester name from Olin Corp.,

was acquired by the French government owned defense contractor giant GIAT

Industries in late 1990.

Many changes were made to the model 70 under USRAC's leadership. They

came up with a detachable magazine in about 1989, then changed the magazine

again the next year when they reintroduced the claw type extractor similar to

the pre-64 type. One problem was that they called it the "pre 64 type".

Many not so knowledgeable customers thought it was indeed a pre 64, as they did

not read the word TYPE when they needed spare

parts. Parts are not interchangeable with the pre 64 guns.

DROP BOX MAGAZINES (DBM) are another confusing issue. The first year production only, DBMs were made for the plunger type extractor & extra magazines are non-existant. After that first year, the claw extractor came into being & the magazine was changed. There are two different magazines, one for the plunger type and the other for the claw type. The physical difference is clearance for the pre 64 type ejector on the left side of the magazine box.

To tell the difference on the shipping box, there is a two letter code, look for a “C” as the second letter, which stands for CLAW. The main visible difference is the follower, the claw type unit has a follower with RH & LH lips extending upward, apparently to force the cartridge rim under the claw extractor. It might be possible to use or modify the claw magazine in the plunger style gun, but NOT the other way around. Also there are NO calibers shown on the shipping box or the magazine itself. Listed below are caliber & codes copied at the time frame these guns were sold for these DBM magazines.

Box Code |

Caliber |

Type of Extractor |

Box Code |

Type of Extractor |

Caliber |

A |

223 Rem. extractor |

push feed extractor |

AC |

claw type |

22-250 only |

|

B |

22-250/243/308 |

“ “ “ |

BC |

“ “ |

243/308 Win |

|

C |

284 Win |

“ “ “ |

CC |

“ “ |

284 Win |

|

D |

270/30-06 |

“ “ “ |

DC |

“ “ |

270 / 30-06 |

|

E |

7mm Rem/300 Win |

“ “ “ Magn. |

EC |

“ “ |

7mm Rem/300Win |

USRA came out with short action guns to accommodate the shorter 223 or 243 length cartridges. Also here was a Ranger version with birch wood & blind magazine about 1990. This version was made in short action 243 & toted as a youth or ladies gun. The year later the blind magazine gave away to the hinged floorplate. They also came out with stainless steel versions.

In about 1992 the BOSS accurizeing system was introduced as an adjustable unit on the muzzle.

A new $15 million plant was opened in October 1994 in New Haven, Conn., the 225,000-square-foot plant house state-of-the-art equipment run by approximately 550 employees.

One bad situation encountered is that now if you need factory repair, ( bolt or barrel replacement), for a gun made before 1981, the USRA factory will send the gun back, saying no parts are available. Parts ARE the same as currently used & are available, BUT since Olin made the gun & not USRA, the lawyers for the factory have decided that since USRA did not make the gun that they will not repair it because of liability concerns.

The above discontinuance of repairs was not limited to the model 70, as it covers all the other models including the model 94.

As of about mid year 2006, USRA plant in New Haven was shut down.

Copyright © 2004-2005 Wisner's Inc. All Rights Reserved